Paragon adds HP Multi Jet Fusion 4200 to its Additive Manufacturing suite Paragon Rapid

3D Printing Material Multi Jet Fusion PA12 in 7 Questions Sculpteo Blog

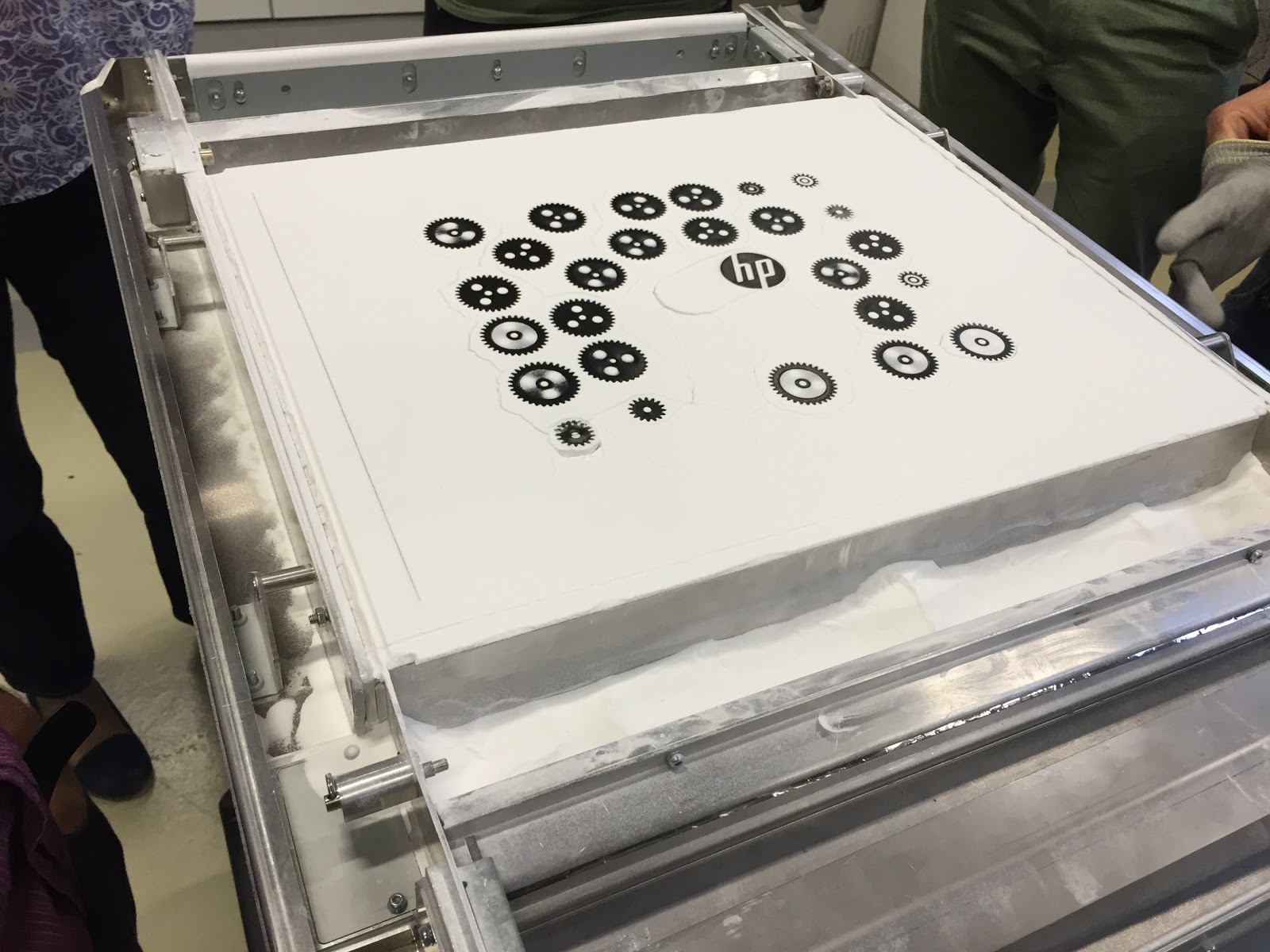

Multi Jet Fusion (MJF) is a powder-bed 3D printing process developed by HP that bonds agent and powder in a process similar to binder jetting. Unlike point-by-point laser-based powder-bed fusion systems, MJF selectively distributes fusing and detailing agents across a bed of powder, and layers are fused together using infrared light.

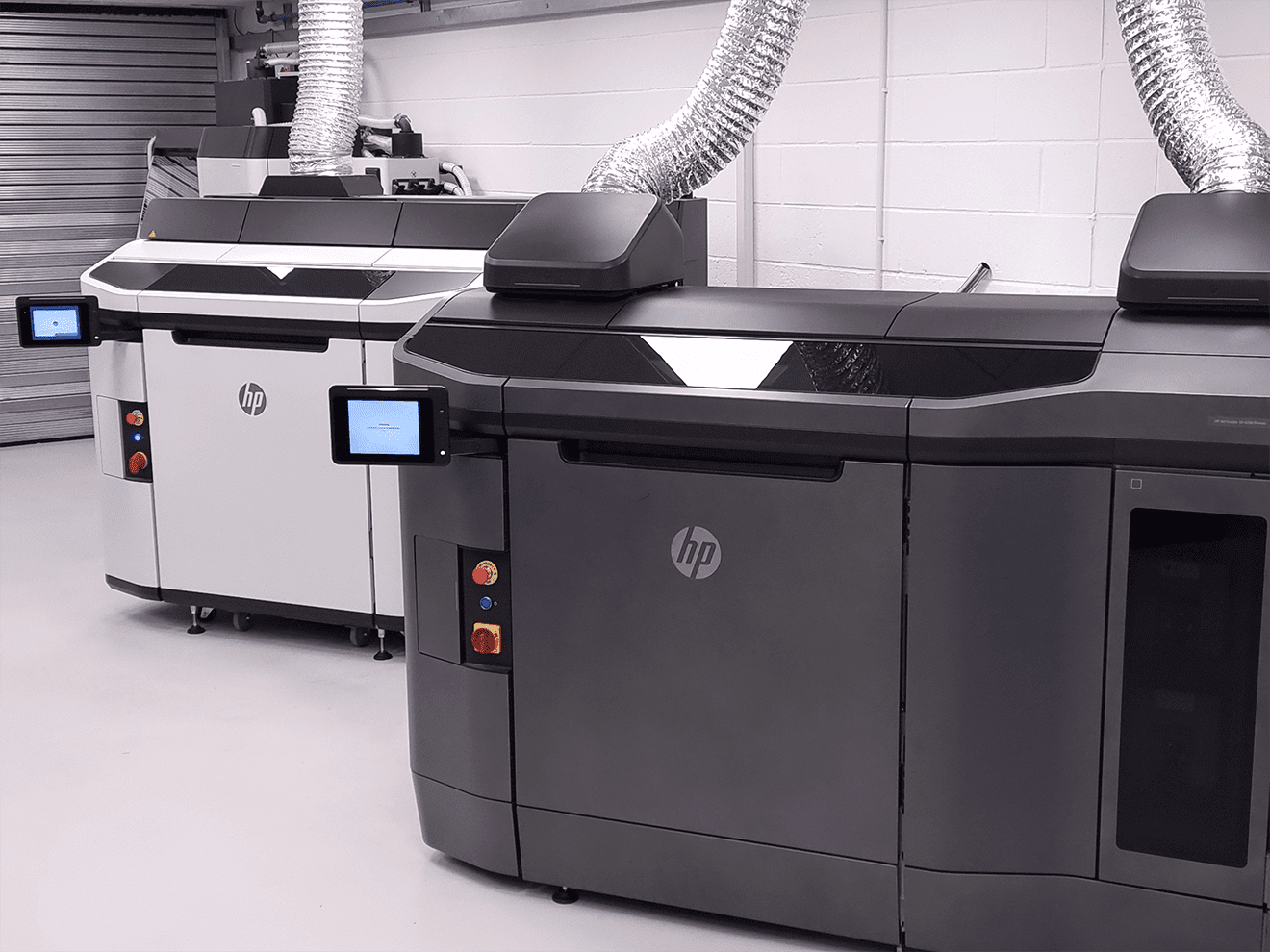

Paragon adds HP Multi Jet Fusion 4200 to its Additive Manufacturing suite Paragon Rapid

How Does Multi Jet Fusion (MJF) Work? - YouTube Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by.

The Complete Guide to Multi Jet Fusion (MJF) 3Dnatives

Multi Jet Fusion is unique in that it doesn't just involve a 3D printer, but features a wheelable build unit that slots into the printer to print on. When you add the processing station to cool parts fast, that makes three different parts used in Multi Jet 3D printing.

HP Unveils Multi Jet Fusion 3D Printing 10X Faster & 10X More Precise Than Current

Watch Explore the complete HP Jet Fusion 5200 Series Industrial 3D Printing Solution HP 3D High Reusability PP enabled by BASF 1 Chemical resistant, 2 weldable, low moisture absorption, functional parts Watch Data courtesy 3 HP 3D High Reusability PA 11 4 Ductile 5, bio-based powder for a reduced carbon footprint 19 Data courtesy 6

Schematic of Multi Jet Fusion (MJF) process (a) HP 3D 4200 printer... Download Scientific Diagram

The Basics of HP MJF. HP Multi Jet Fusion is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other.

HP Multi Jet Fusion™ technology Entry iF WORLD DESIGN GUIDE

Multi Jet Fusion is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day. Final parts exhibit quality surface finishes, fine feature resolution, and more consistent mechanical properties when compared to processes like selective laser sintering.

HP Multi Jet Fusion / MJF 3D Printing Learn More & Get A Quote

Multi Jet Fusion (MJF) is one of the more recent additive manufacturing (AM) technologies on the market, and it has a lot of potentials. Hewlett-Packard (HP) developed MJF 3D printing in 2016. It is a type of Binder Jetting 3D printing technology, and HP claims it is faster, cheaper, and produces more functional parts than rival technologies.

3D Printing with Multi Jet Fusion (MJF) The Technology House

Among the many 3D printing technologies available, Multi Jet Fusion (MJF) stands out for its speed, accuracy, and cost-effectiveness. In this beginner's guide, we will dive deep into the MJF 3D printing process, learning how it works, how to design for it, and how to make the most of it while saving costs. So, let's get started!

The Benefits of Multi Jet Fusion 3D Printing 3D Printing Today 3D Printing News and 3D

HP Jet Fusion 4200 Industrial 3D Printing Solution Produce quality parts while optimizing productivity and cost with our industrial 3D printing solution Industrial prototyping and final part production Quality, functional parts • Ideal for functional prototyping and short-run production.

Shapeways Receives First HP Multi Jet Fusion 3D Printer

From prototype to production, get quality parts at consistently low prices. Your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price.

Multi Jet Fusion MJF 3D Printing Avid Product Development

Multi Jet Fusion is an additive manufacturing technology developed by HP and unveiled in May 2016, causing industry-wide excitement and apprehension in equal measures. MJF sits within the Powder Bed Fusion (PBF) family of technologies and shares aspects of both SLS and Material Jetting processes.HP claims that MJF is up to 10 times faster than.

HP Officially Launches Multi Jet Fusion 3D Printers

Multi Jet Fusion (MJF) is a 3D printing process for building prototyping and end-use parts fast. This article explains how MJF works and its main advantages. What is Multi Jet Fusion (MJF) 3D printing? How was MJF developed? How does Multi Jet Fusion work? What materials does MJF use? How does MJF post-processing work?

Multi Jet Fusion Plg Labs

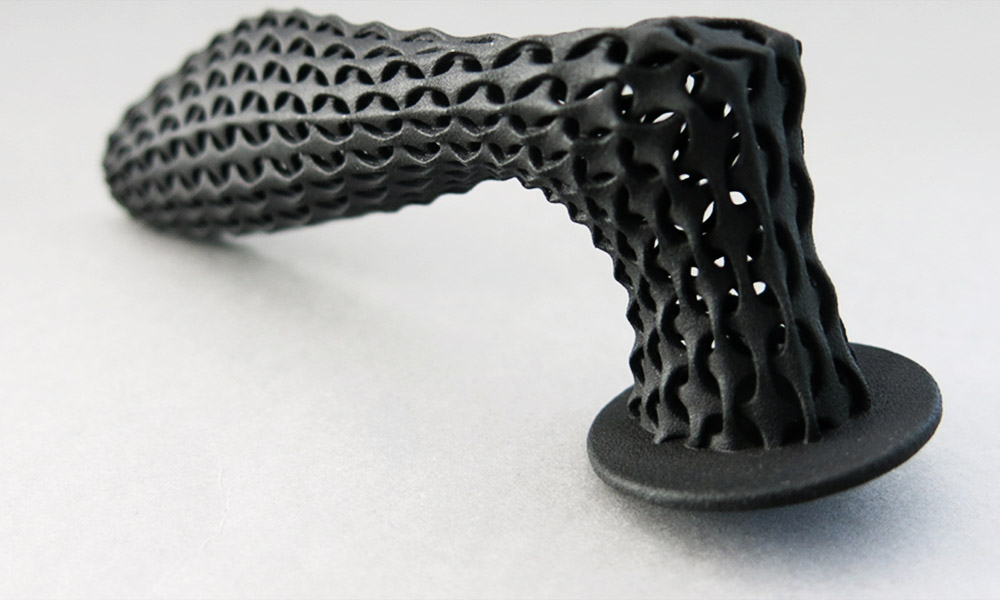

Multi jet fusion is a powder bed fusion technology involving a fine layer of powder spread over a build platform that the MJF printer fuses by selectively applying heat with a fusing and a detailing agent. Therefore, it is a multi-agent process of additive manufacturing. Multi Jet Fusion printed object

All about HP Multi Jet Fusion, industrial 3D printing Bitfab

MJF (Multi Jet Fusion) is a powder-bed 3D printing technology that was developed by HP in 2016. HP Multi Jet Fusion creates 3D printed parts using powdered nylon, polypropylene, or TPU (Thermoplastic Polyurethane) as the raw material. Infrared heat lamps acting with fusing and detailing agents densify the powder into a final part.

HP Prints Parts for its Multi Jet Fusion 3D Printer

What is Multi Jet Fusion (MJF) and How Does it Work? Learn what Multi Jet Fusion (MJF) is and how it works. We'll discuss the 3D printing process, materials,.

15+ Multi Jet Fusion 3D Printing Images Abi

Multi Jet Fusion 3D printing, invented by HP, is an additive manufacturing method of choice for a wide range of industries. Read on to learn more.